Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

Introduction of Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

Fish feed extruder,also called fish feed pellet mill,is widely used for producing variety materials into high-grade aquctic feed pellets for fish,catfish,shrimps,crab etc.The final feed pellets have unique shape and good taste,high nutrition and smooth textures.For feeds of fish and shrimp,the floating time no water surface can be adjusted by the extrusion degree adjustment when extruding the pellets.Currently,floating fish feed extruder has become an ideal for small and medium fish farm(catfish,tilapia,shrimp etc.)

Advantages of Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

1. This fish food extruder is widely used for producing floating feed pellets of all kinds of aquatic animal.

2. Advanced technology and humanized design ensures easy operation and reliable performance.

3. High efficiency, low power consumption

4. Screw sleeve of this small fish food extruder adopts enchase alloy steel strip structure, which guarantees long service life.

5. Different moulds can be chosen to make pellets with different diameters and shapes.

6. Feed pellets dia. Is 1-20mm.

Common Raw Material for Making Nutritional Feed of Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

Our fish feed making machine is based on the raw material of corn meal, flour, Wheat middling, Wheat bran, rice bran,

soybean meal, cottonseed meal, fish meal, bone meal, meat meal and etc.

------ Moisture of raw material: 20% -25%

------ Raw material type: Powder

------ Fineness of material: 60-80 mesh

Fish feed making machine can be classified into dry type machine & wet type machine.

*** Dry type --- Easy operation and simple.

*** Wet type--- With conditioner and need steam boiler as supporting device to work, has high yield than dry type in the same power.

Parameters of Dry type floating fish feed extruder machine,Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

| Model | Capacity | Motor power | Feed power | Cut power | Screw diameter |

| HH-D60 | 120-150kg/h | 15KW | 0.4KW | 0.4KW | 60mm |

| HH-D70 | 180-250kg/h | 18.5KW | 0.4KW | 0.75KW | 70mm |

| HH-D80 | 300-350kg/h | 22KW | 0.6KW | 1.5KW | 80mm |

| HH-D90 | 400-450kg/h | 30KW | 0.8KW | 2.2KW | 90mm |

| HH-D120 | 500-700kg/h | 55KW | 1.1KW | 2.2KW | 120mm |

| HH-D135 | 800-1000kg/h | 75KW | 1.1KW | 2.2KW | 135mm |

| HH-D160 | 1200-1500kg/h | 90KW | 1.5KW | 2.2KW | 155mm |

| HH-D200 | 1800-2000kg/h | 132KW | 1.5KW | 3KW | 195mm |

Parameters of Wet type floating fish feed extruder machine,Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

| Model | Capacity | Motor power | Feed power | Cut power | Screw diameter |

| HH-W60 | 200-250kg/h | 15KW | 0.4KW | 0.75KW | 60mm |

| HH-W70 | 300-400kg/h | 18.5KW | 0.4KW | 0.75KW | 70mm |

| HH-W80 | 500-600kg/h | 22KW | 1.1KW | 0.75KW | 80mm |

| HH-W90 | 700-800kg/h | 37KW | 1.1KW | 1.1KW | 90mm |

| HH-W120 | 1000-1200kg/h | 55KW | 1.1KW | 1.1KW | 120mm |

| HH-W135 | 1400-1600kg/h | 75KW | 1.5KW | 2.2KW | 135mm |

| HH-W160 | 2000-3000kg/h | 90KW | 2.2KW | 2.2KW | 155mm |

| HH-W200 | 3000-5000kg/h | 132KW | 2.2KW | 3KW | 195mm |

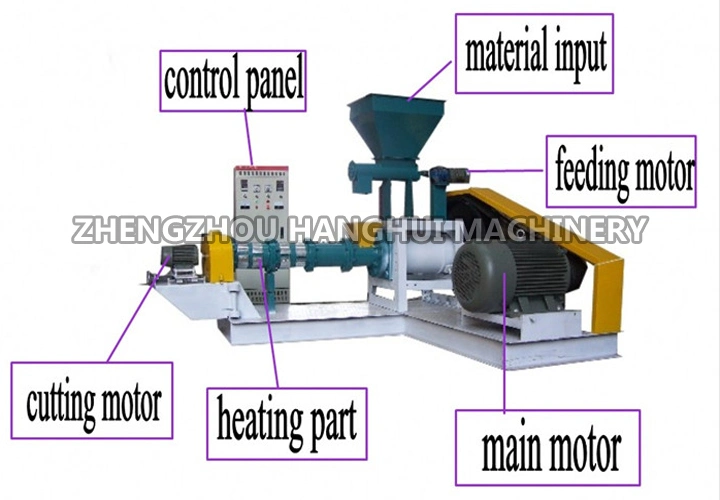

Pictures of Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

We also have automatic line for Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

Material crushing----powder mixing----pellets extruding---pellet drying---pellet cooling---pellet packing.

1) Crusher----To crush the raw material into powder.

2) Mixer -------To make all kinds of powder mixed evenly.

3) Extruder----To make many kinds of feed pellet. Such as fish feed, pet feed.

4) Dryer--------To remove the extra moisture of the pellet.

5) Cooler------ To reduce the temperature of the pellet after dring.

6) Packaging-- After cooling the feed pellet, we could package it.

Final product of Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line

Packing and shipping of Factory Price Floating Sinking Aquatic Feed Machine Fish Feed Extruder Feed Pellet Granulator Production Line