Horizontal ribbon mixer is mixing equipment with high efficiency, high uniformity, high loading coefficient but low energy cost, low pollution, and low crush. The special design of the double ribbon mixes the materials into high uniformity in a few minutes. On the other hand, ribbon mixer shows wide application from powder mixing,powder-liquid, to paste or materials in high specific gravity and becomes one of the most popular single shaft horizontal mixing equipment.

Horizontal ribbon mixer consists of drive disk assembly, double layer ribbon agitator, U-shape cylinder. Inside ribbons move materials toward the ends of the ribbon blender whereas the outside ribbons move materials back toward the center of the ribbon blender, therefore, materials get fulling mixing. Materials flow direction is determined by ribbon angle, direction, twining method. Materials outlets are in the middle of the cylinder bottom. Out side ribbon driven by the main shaft moves the materials to discharge ensures no discharging dead zone.

Production capacity:30L-18,000L

Materials Specific Gravity ≤5g/cm3

Mix time:6-8 minutes

Driven power:3KW-132KW

Equipment materials:304,321,316L,carbon steel

Technical Data

| Model | Capacity(L) | Power(kW) | Speed(r/min) | Overall Dimension(mm) | Weight( Kg) |

| WLH-100 | 30-60 | 3 | 60 | 1500×500×700 | 400 |

| WLH-300 | 90-180 | 5.5 | 41 | 2000×700×1000 | 800 |

| WLH-500 | 150-300 | 7.5 | 41 | 2500×800×1400 | 1200 |

| WLH-1000 | 300-600 | 11 | 33 | 2700×1000×1450 | 1800 |

| WLH-2000 | 600-1200 | 15 | 33 | 3400×1200×1700 | 2300 |

| WLH-3000 | 900-1800 | 18.5 | 33 | 3800×1300×1950 | 3200 |

| WLH-4000 | 1200-2400 | 22 | 26 | 4100×1400×2000 | 4000 |

| WLH-5000 | 1500-3000 | 30 | 26 | 4200×1500×2000 | 4500 |

| WLH-6000 | 1800-3600 | 37 | 26 | 4500×1700×2100 | 6000 |

| WLH-8000 | 2400-4800 | 45 | 20 | 5000×1800×2200 | 7000 |

| WLH-10000 | 3000-6000 | 55 | 20 | 5000×1900×2500 | 8000 |

| WLH-15000 | 4500-9000 | 90 | 20 | 6500×2100×2800 | 9800 |

| WLH-20000 | 6000-12000 | 110 | 18 | 7500×2400×3000 | 13000 |

| WLH-30000 | 9000-18000 | 132 | 16 | 9000×2600×3500 | 18000 |

Note:

The data can be used for reference only

The above list max processing capacity is calculated as per powder with specific gravity 1 as a medium.

The model selection should depend on the comprehensive factors such as materials viscosity, specific gravity, etc

Product application

The material can be carbon steel, 304, 316L, and 321;

Powder contact parts suggest stainless steel

Multifield surface treatment include mirror polish, sandblasting and

Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

The driven unit, power, and output speed are varied according to different raw material, starting method, and processing.

Options for motor: general motors, explosion-proof motors,

Heavy duty gear reducer with a direct connection

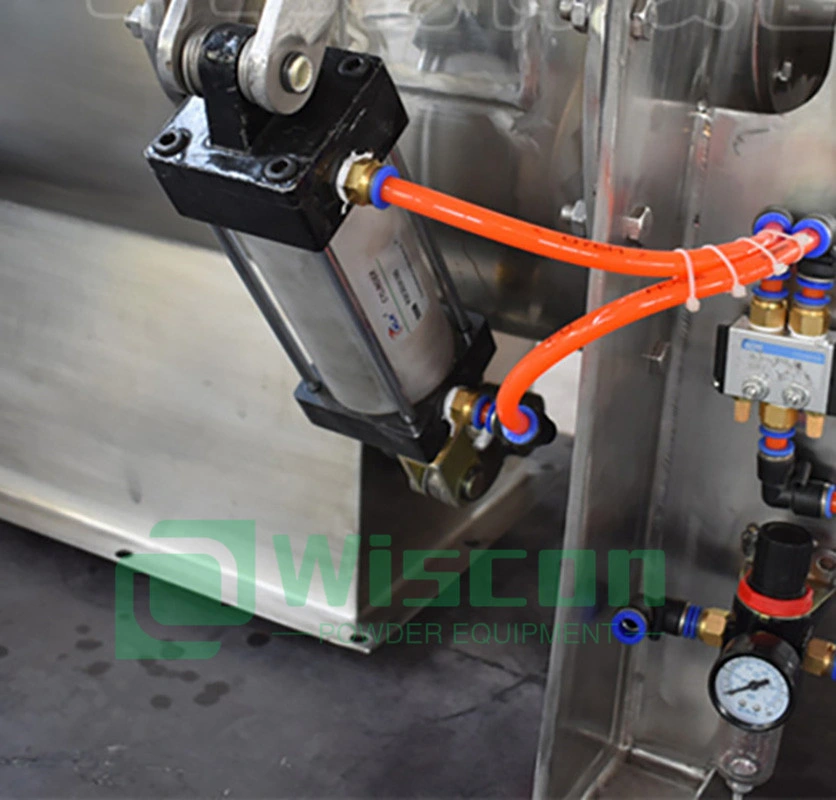

Standard valve for horizontal mixer is pneumatic planar flap valve. When close the valve, the planar flap match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, butterfly valve, etc.

About Wiscon

We are the professional powder equipment supplier which applied in chemical, pharmaceutical, agrochemical, food, new material, etc. industries.

We can supply a perfect turnkey project with design, manufacture, installation, commissioning & after-sale service.

Our outstanding reputation for products high-quality, durable, customized solutions is widely recognized. We partner with our customers and help them to keep their operations safe and controlled.

Our core values―respect, integrity, Excellent quality, close proximity to our customers―guide our actions and behavior every day.

Frequently Asked Questions

Q: What's the quality of your products?

A: First of all, we select qualified parts supplier, then We have strictly quality control during production, You can rest assured with the quality absolutely.

Q: What to do if the machine has a problem?

A: We provide 24-hours customer hotline service and provides technical support free of charge within or after warranty; If beyond 12 months, customers only bear the freight and accessories cost.

Q: How long is the warranty for your equipment?

A: Our warranty period is 12 months.

Q: What is your payment term?

A: Our payment term is: T/T or LC. Also, other payment could be negotiable;

Q: Could you accept customized design?

A: All our products designed base on customer requirements and site conditions, we can supply customized designs for better machinery working.

Q: how to reach your company?

A: We located in Wuxi city, Jiangsu province, our factory is close to shanghai airport, about an hour, if you are to visit the factory. We can pick you up at the airport. Welcome to our company.

Q: How to choose the suitable powder blender equipment?

A: The proper selection of the powder blender depends on the following requirements:

1) What types of materials do you want to mix? ( material's name? density?)

2) Any special features for materials? like fluidity, viscosity, strong acid and alkali, abrasion, easy fragile, etc

3) What about output per batch capacity by volume?

4) What kinds of materials are you considered for contact parts materials? (Normally 304,316L,321)

5) Which equipment you will use for upper port powder loading and bottom port discharging?

6) How about your plant electricity power? (normally 50HZ 380V-415V or 60HZ 220-480v)